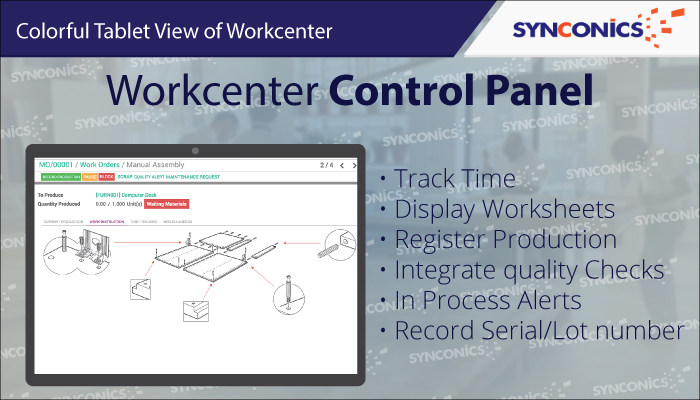

Newly Added Tablet View in Odoo MRP v10

Record work operations on tablets at all the work centers:

Quality control

Barcode support

Trigger issues

Record productions

Display worksheets

Time tracking

This is what the Workcenter control panel looks like on a tablet.

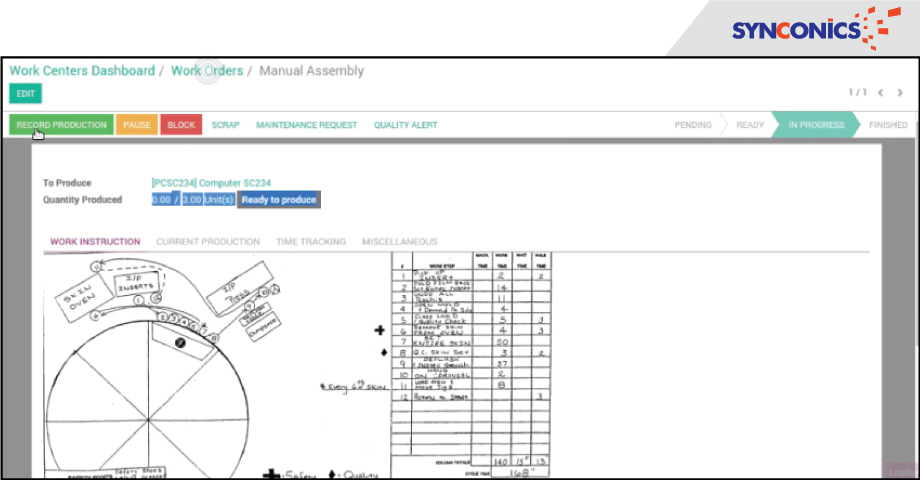

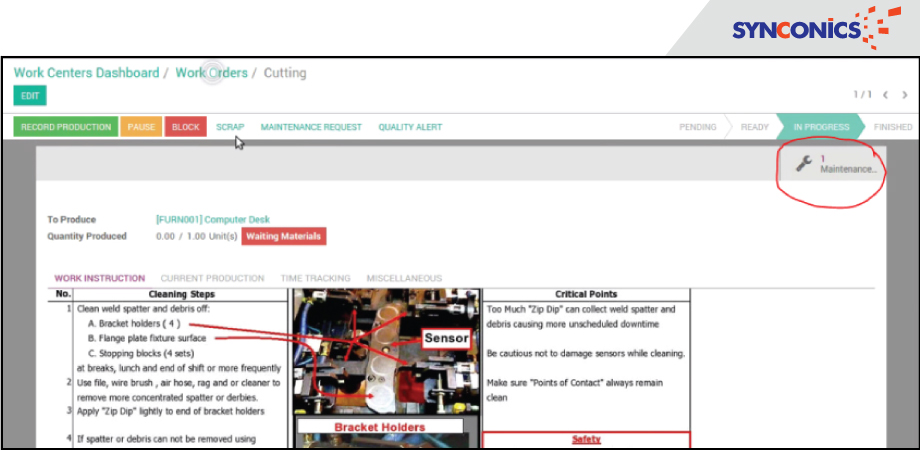

You have the worksheet with all the instructions and various operations on colored tabs. We will see an example below: Once we click on start working, we will see different colored tabs – Record Production, Pause, Block, Scrap, Maintenance Request & Quality Alert. As soon as we click Start Working the system starts to record time. If there is a lunch or tea break we put on Pause, or if there is a quality or maintenance issue in the assembly line we can record it live rather than create paperwork and go around for approvals. The same can be done if any part is to be scrapped during production, one can just record it so it reflects in inventory as well.

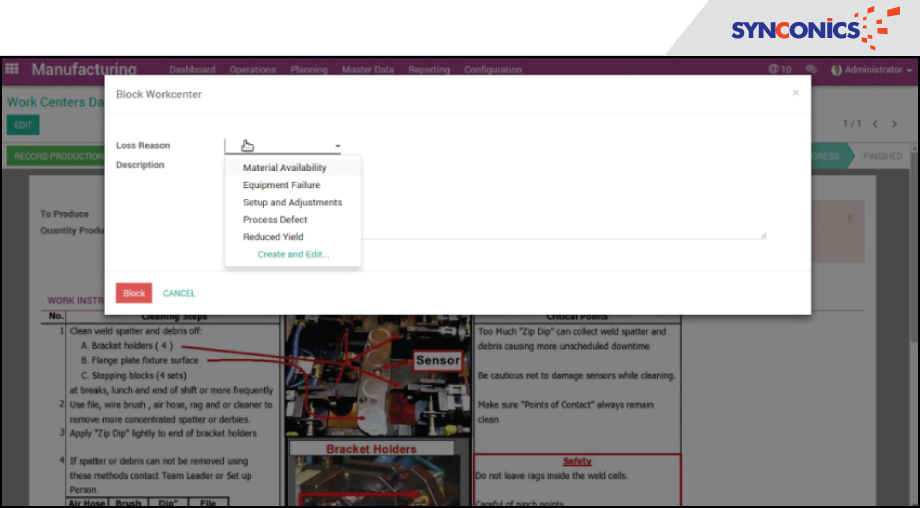

There could be a scenario where production has to be stopped due to reasons beyond our control. We use the Block function in that case. Loss reasons could amount from Material Availability, Equipment Failure, Setup and Adjustments, Process Defect, Reduce Yield or a new can be created.

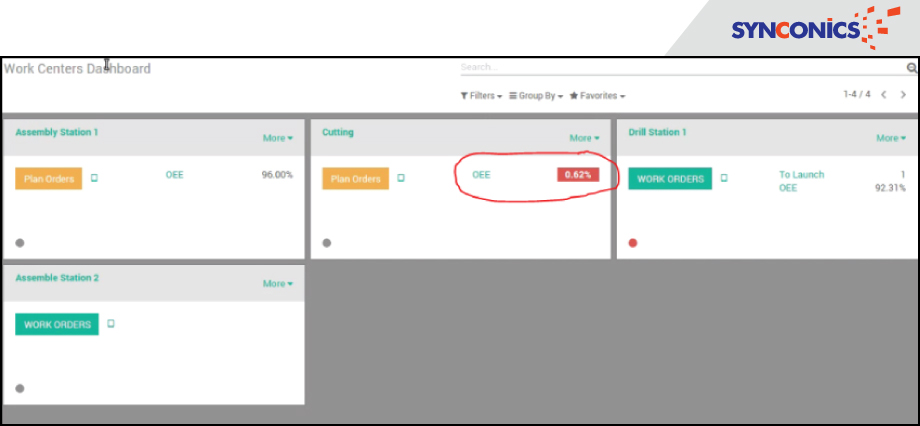

Now the manager will get a red dot when he looks at his dashboard for the work center which has been blocked. Overall equipment efficiency (OEE) will be impacted and so will all the KPIs.

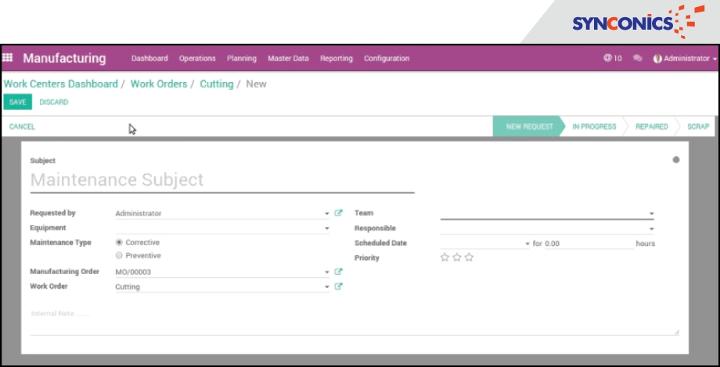

A maintenance request has to be launched immediately. Through the mail gateway, the request will be sent to the maintenance department and has to be addressed as the case may be. As in normal mails, the followers will get a mail so concerned persons will be in the loop and track progress. If someone is interested in this conversation he can follow as well.

We can now see that there is one maintenance request for our work center.

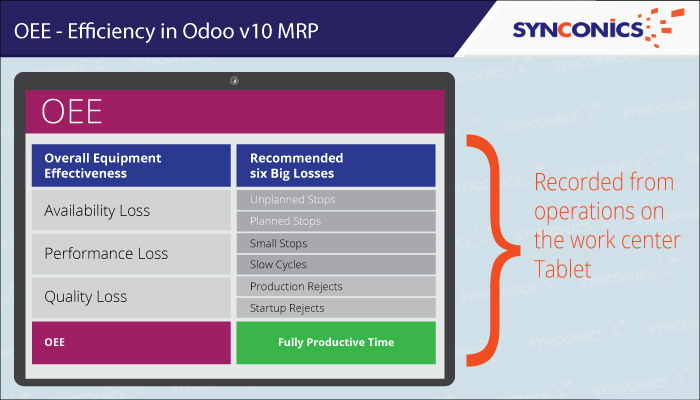

If we go back to our work centers, we notice that one of the centers has a very bad OEE (Overall equipment efficiency).

It is the way in which we compute the performance of your manufacturing operations. It computes the percentage of the actual time you do real manufacturing. Rest is divided by 6 big losses defined by the TPM methodology (Total Productive Maintenance).

One of the major goals of the TPM and OEE programs is to reduce and/or eliminate what is called six big losses – the most common cause of equipment-based productivity loss in manufacturing.