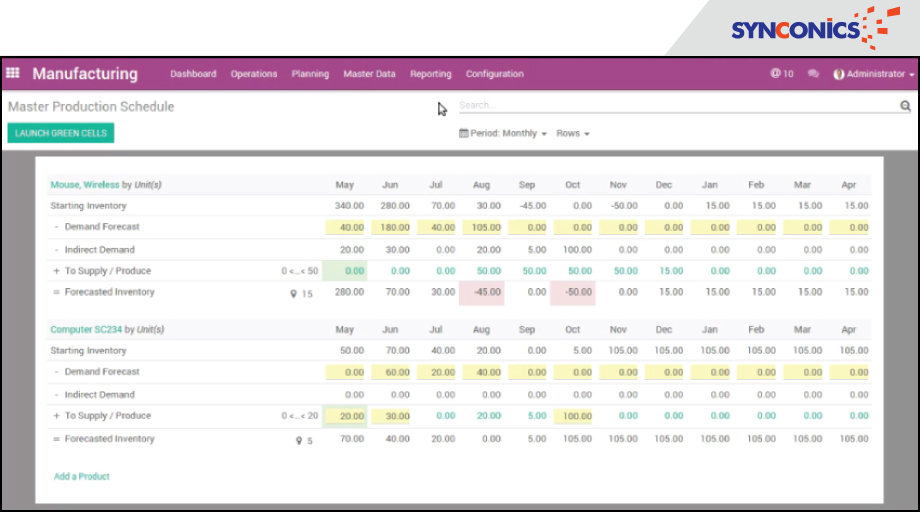

Master Production Schedule is the master of all schedules in MRP Odoo10

To automate scheduling, along with existing Minimum Stock Rules and Make-to-Order newly added MPS (Master Production Schedule) will trigger manufacturing order (it could also be used for Purchase as well) based on customer demand.

Looking at Demand Forecast one will come to know how much production is needed (Go to Manufacturing and under Reporting, you will find MPS).

One can work by months, weeks or days depending on the industry. There could be interaction between the two products like a computer could also be linked to a mouse. It works taking into consideration the Starting Inventory, Demand Forecast, Indirect Demand (if any – as products might be correlated,) & to Supply / Produce. We can put constraints on producing a certain number only, depending on business forecast.

It is very efficient and we can show it to suppliers the forecast of the demand and ask to prepare accordingly. For example someone has to produce a bike in 3 months, however wheels take 2 months of production time – so MPS will calculate the figures itself based on the timeline. Figures can be changed as well.

Depending on the lead-time, figures in green background should be launched first to suppliers. By launching Green Cells it will trigger MO & POs. Constraints can be easily changed – Minimum, Maximum, Forecasted Quantity etc. One can filter and print certain Rows for specific Suppliers.