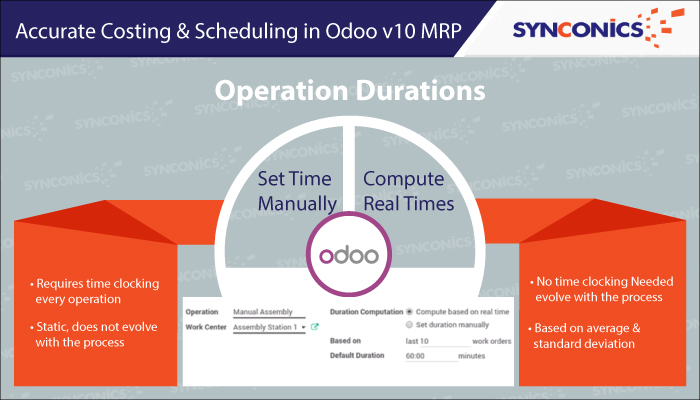

In MRP Odoo10 operation hours are based on average and standard deviations

Clocking every operation manually is still prevalent to this day. It hasn’t evolved with the process. What Odoo MRP10 has come up with is a very innovative tool that operation hours are based on average and standard deviations. The aim is to get accurate timing which will help in getting accurate costing and scheduling.

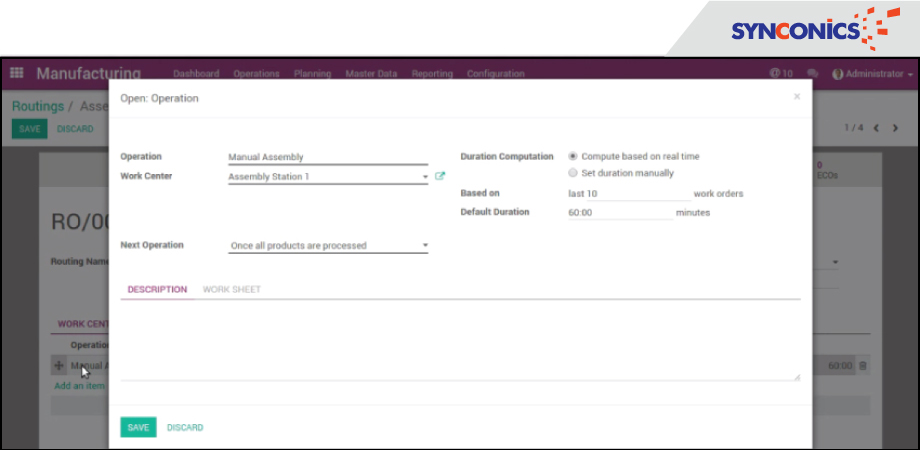

Let us see how it can be done. We go to Master Data and then Routings. When we select any listed Routing, under work center operations we go to Manual Assembly – Most of the software’s out there set the operations manually. However in Odoo MRP v10 you have the option of selecting computation based on last 10 work orders (need a tablet at every work center).

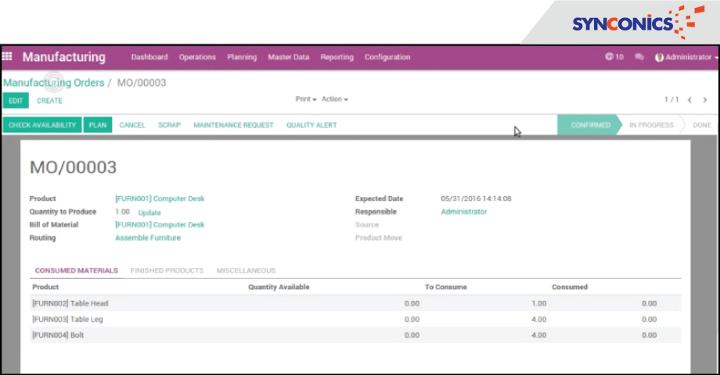

This gives the flexibility to the planner under planning section and subsequently launch all MOs or Orders to Plan depending upon priorities based on expected date that comes from the Scheduler.

Once the MO is confirmed we can manually escalate it to “in progress” stage by pressing Plan. It will generate work orders that are the jobs to be done. It will use the capacity planning and Gantt chart.

The advantage here is that compared to time clocking where operators work slowing, the average time is calculated based on standard deviation.

To assist you more please mail us on contact@synconics.com and also explore Synconics.com